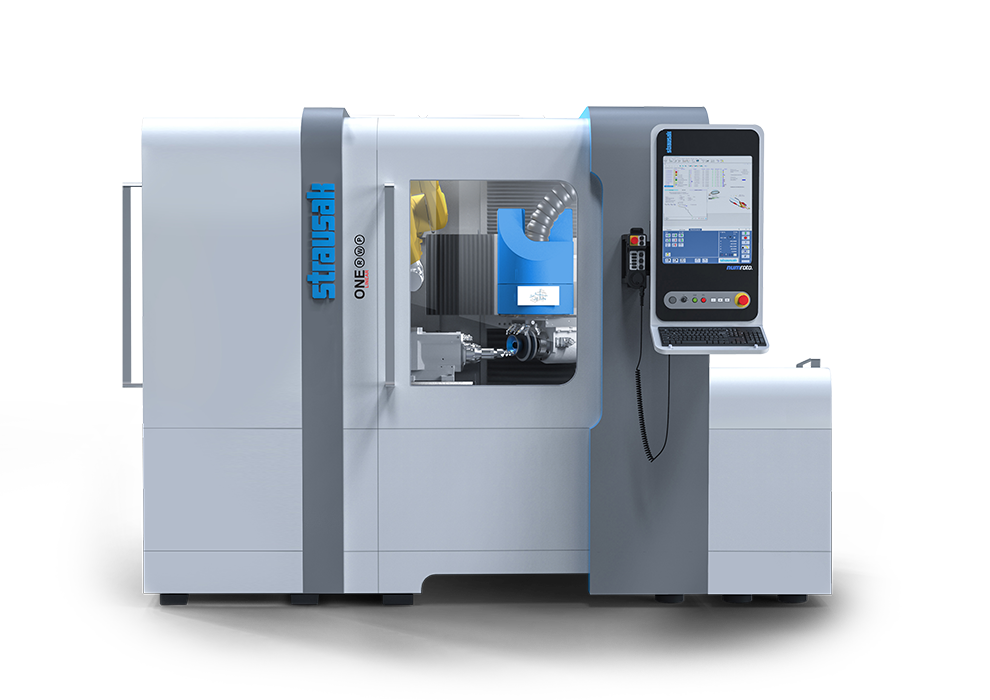

Big achievement in a small footprint

Modern workshops need flexibility, efficient floor space use, lean processes, short setups, and small machines.

However, compactness will not impact capacity.

- fluting length up to 425 mm (16.73”)

- cylindrical grinding up to Ø170 mm (6.7”)

- 24 kW (32 HP) spindle

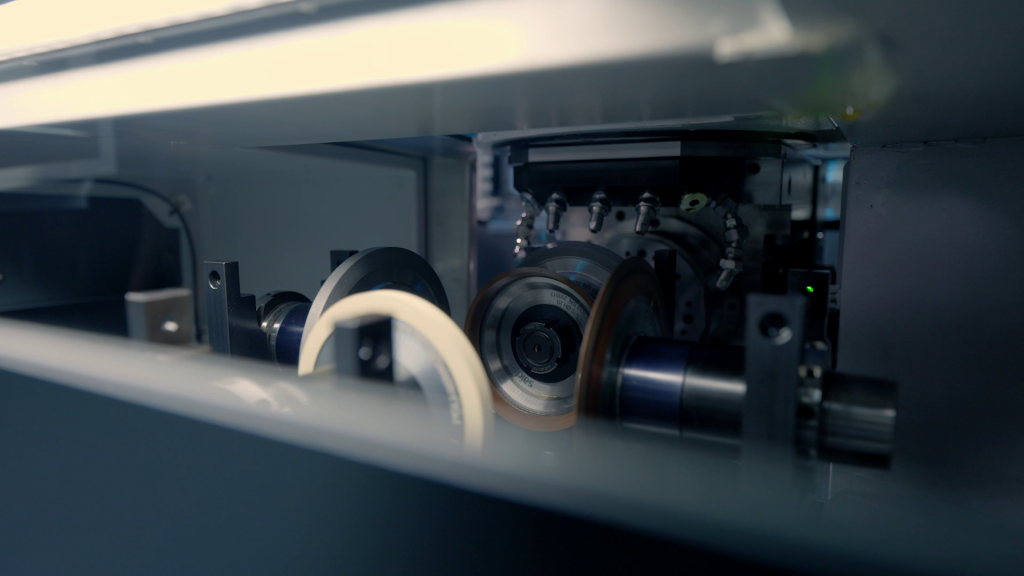

- integrated tool loader

- integrated wheel changer